Charlie Rysenga

Mostly human and part goose

Arburg Controller Rebuild

by

At i3Detroit we are fortunate to have two vintage injection molders. An Arburg C4b and an Arburg ALLROUNDER 150. Both have nameplates that suggest they were made in West Germany and both came to us in a non-working condition. The ALLROUNDER 150 was the less working of the two and the subject of this post.

The 150 has two primary electronic controls one to control the hydraulic motions of the machine and a pair of temperature controllers to heat the barrel. They are self-contained modules that are really easy to remove from the machine.

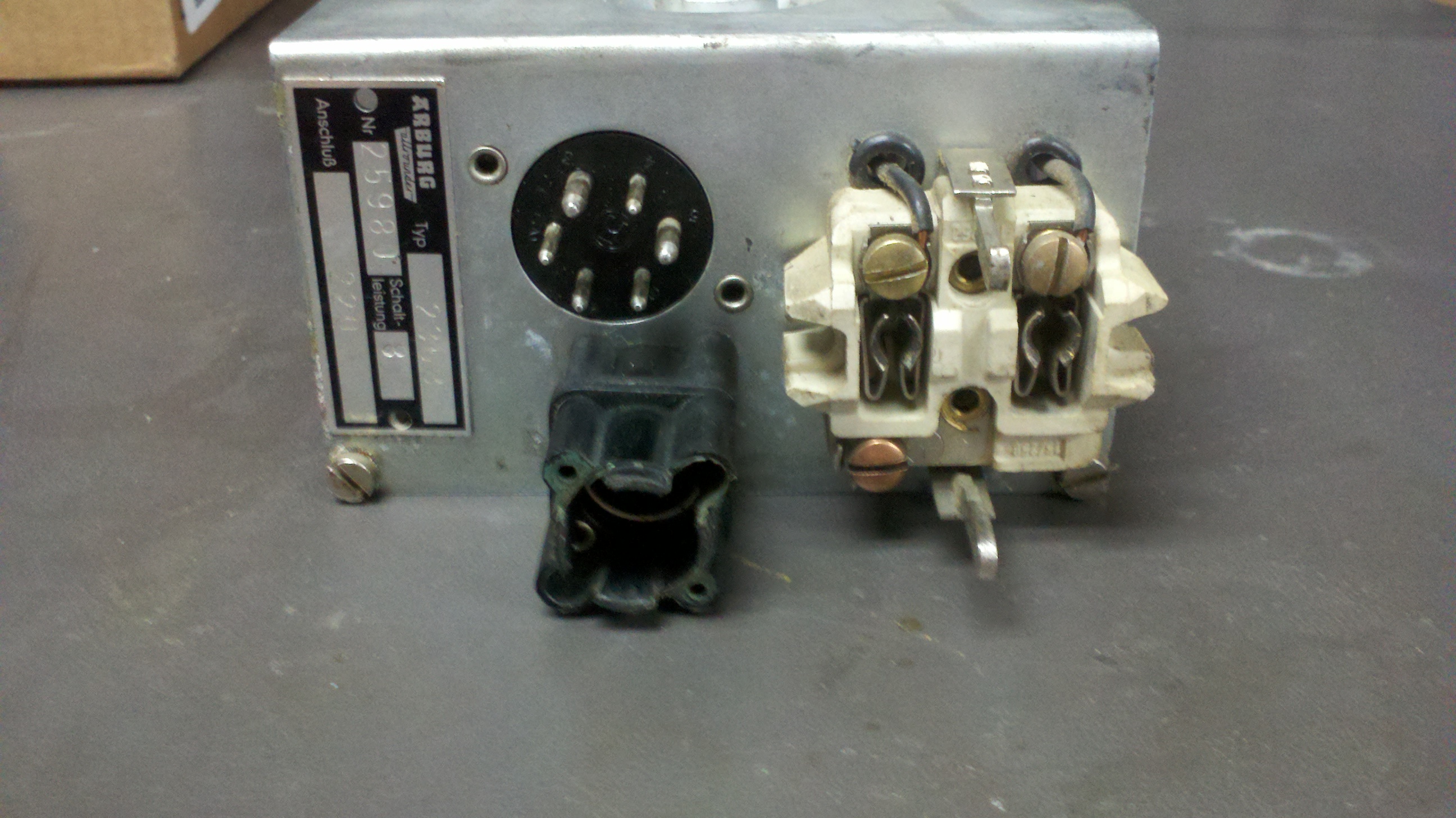

Front of Temperature Controller

Front of Temperature Controller

Back of Temperature Controller

Back of Temperature Controller

When the 150 arrived at i3 it showed a number of issues. They were mostly mechanical and caused by a long period of disuse. The issues included rotten hoses, dirty/old grease, etc. One of the big issues was that the temperature controllers did not work. One of them would never reach temperature and the other would overheat and cause the plastic to burn.

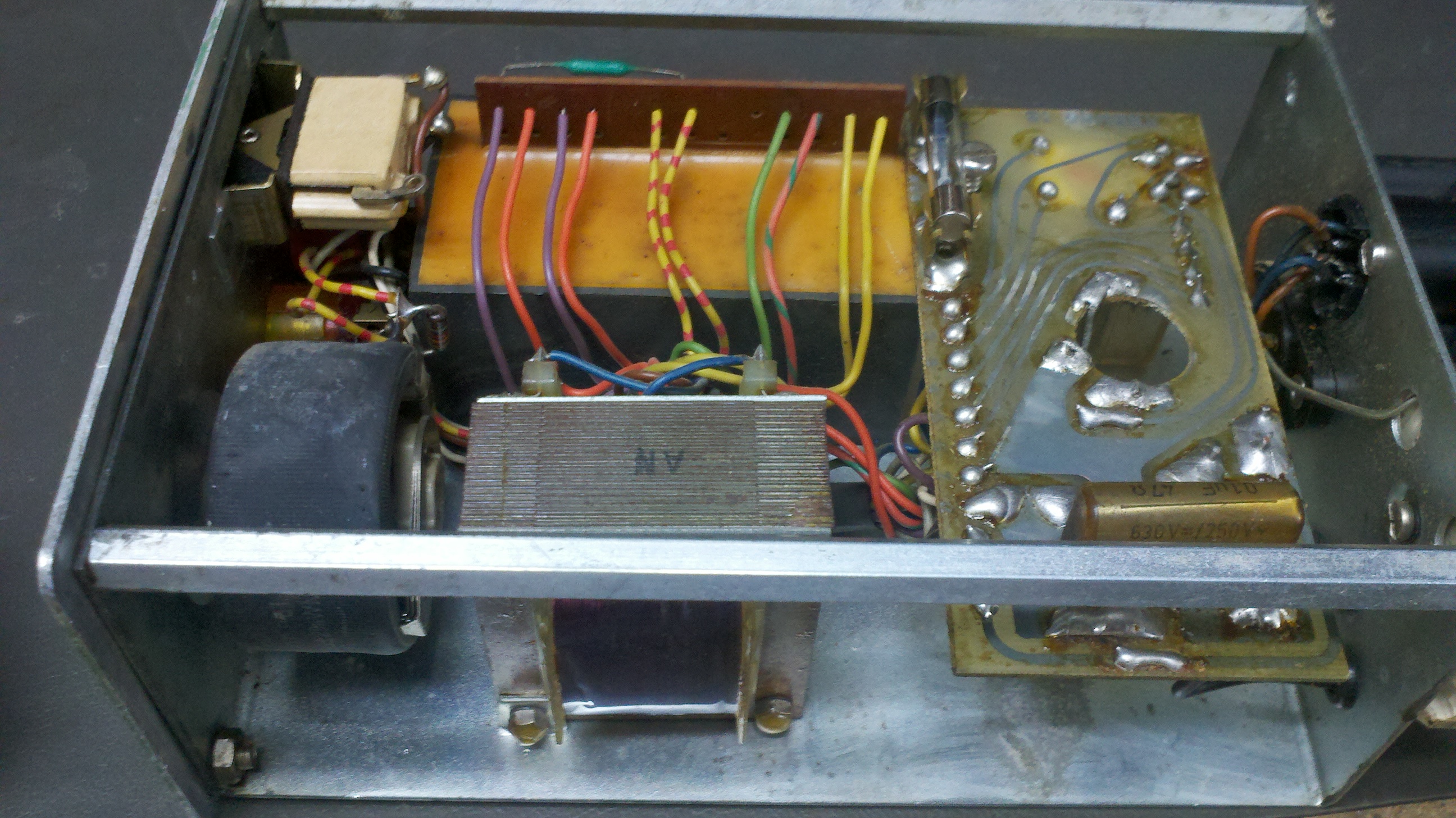

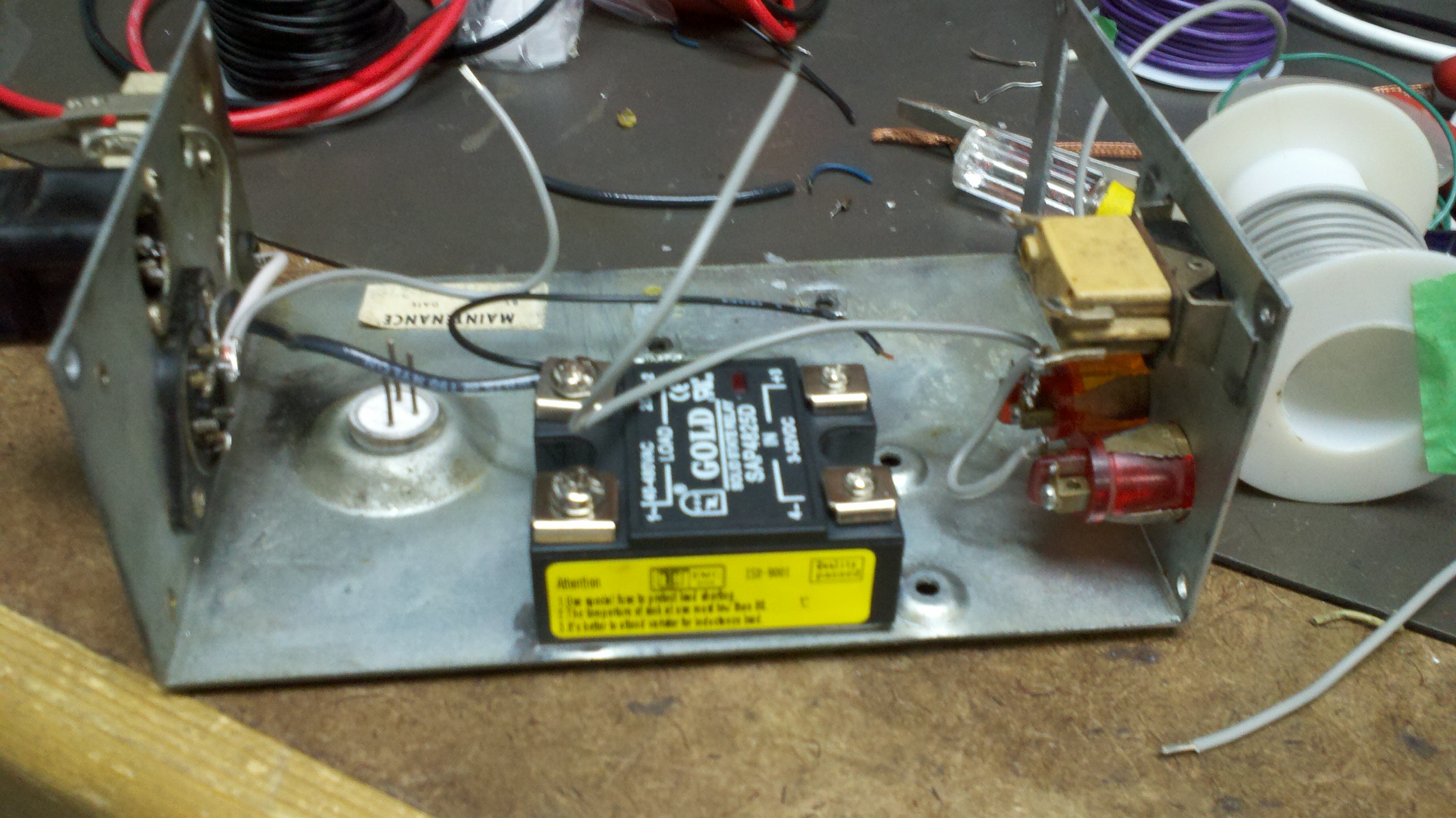

Controller Insides

Controller Insides

Upon removing the modules I was greeted with the above. The controller has four basic components. There is a variable resistor to set the desired temperature, a transformer that powers the controller, a circuit board with triac that routes power, and a PID controller enclosed in epoxy. I poked around the controller to see if there was anything simple like a blown fuse or broken wire but no such luck. Since the PID controller is a sealed module it will be easier to reproduce the functionality than to excavate the circuitry from the epoxy.

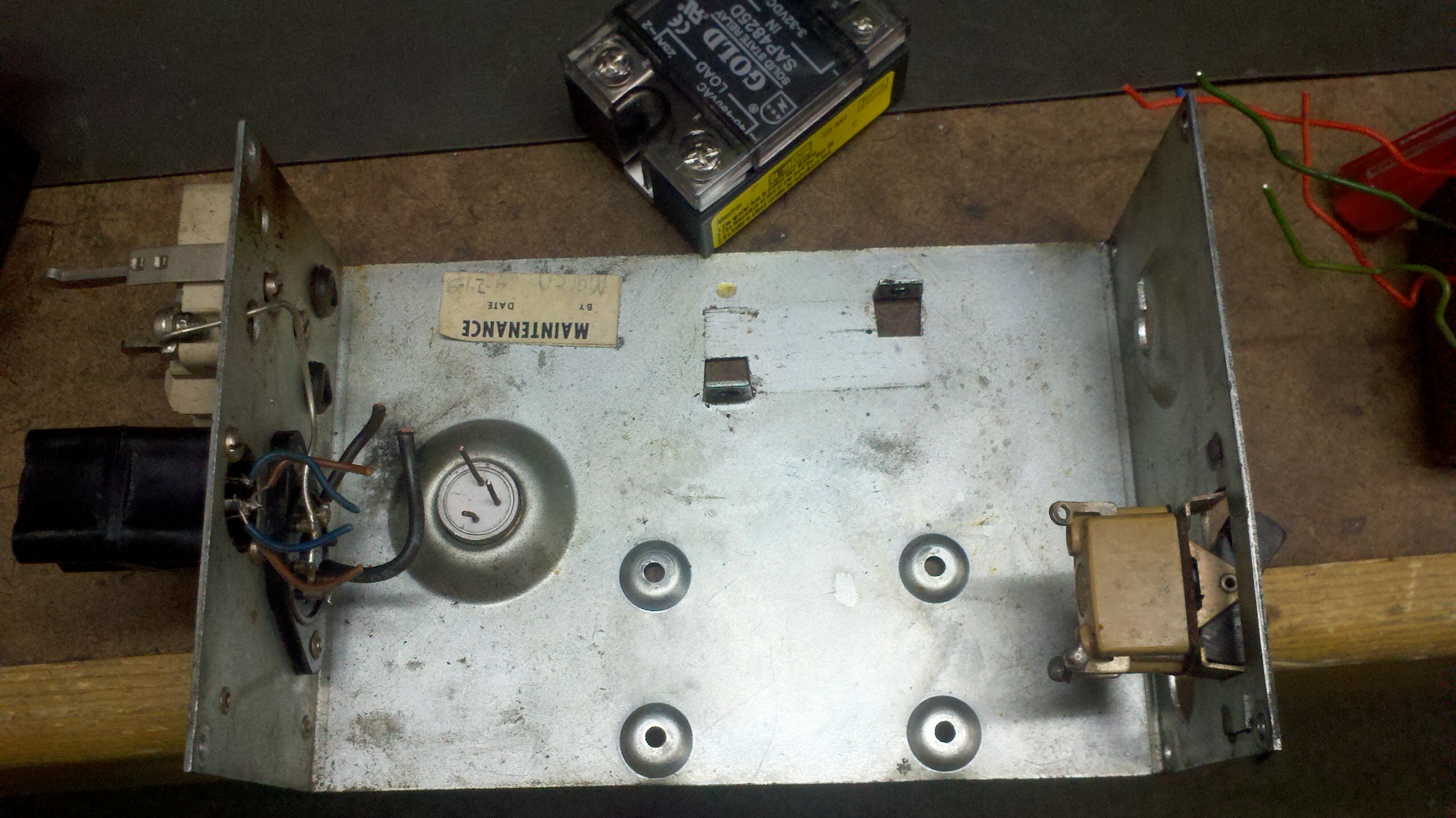

Empty Controller Body

Empty Controller Body

I removed the guts from the controller to give myself a clean slate to work with. I ended up leaving the triac in because it would be hard to remove (it being pressed into the case) and I could not bring myself to cut the leads off.

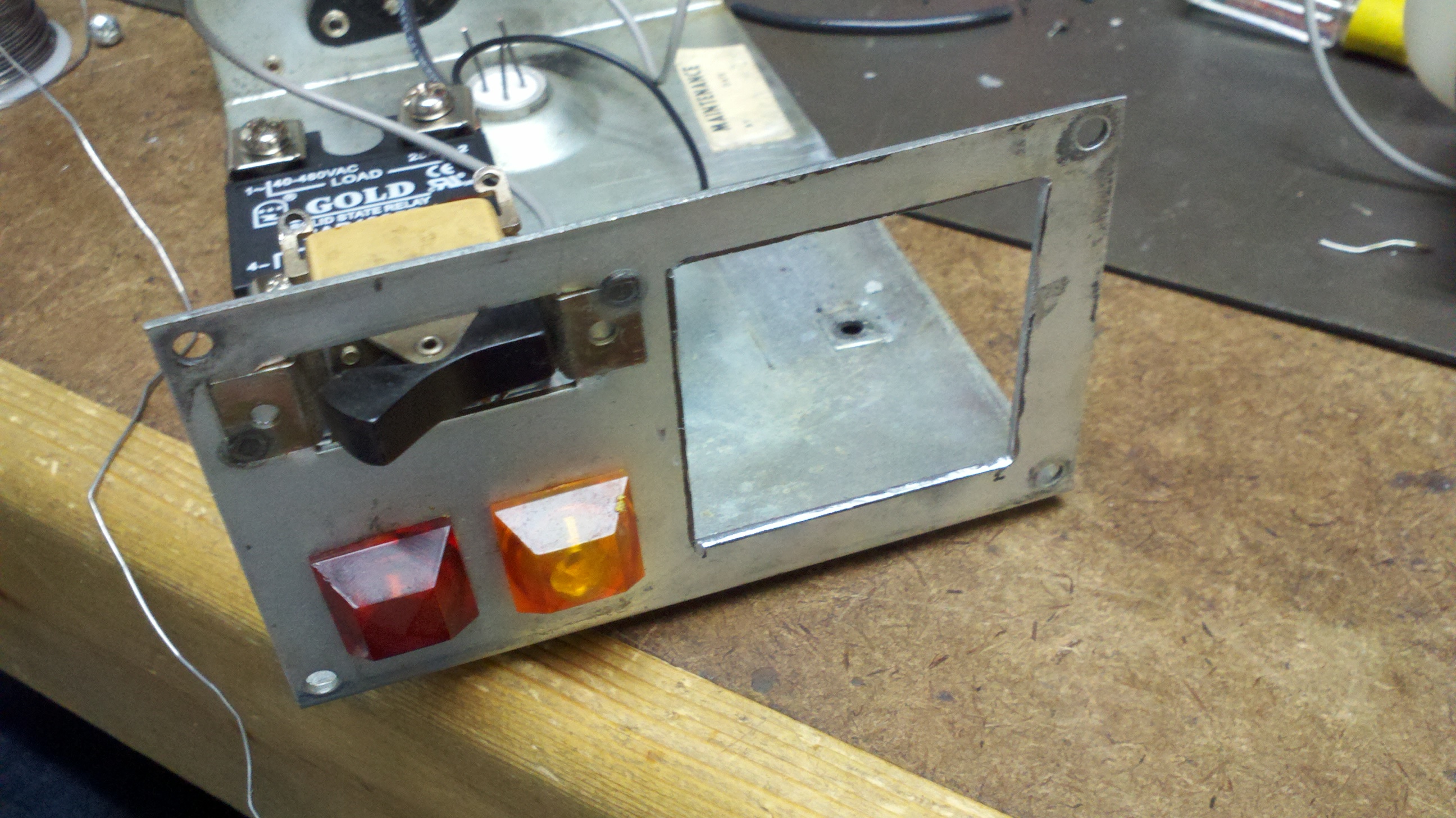

Hole for PID Controller

Hole for PID Controller

I used a Dremel to cut a hole in the front of the enclosure. This was the most time consuming part of the whole rebuild for some strange reason.

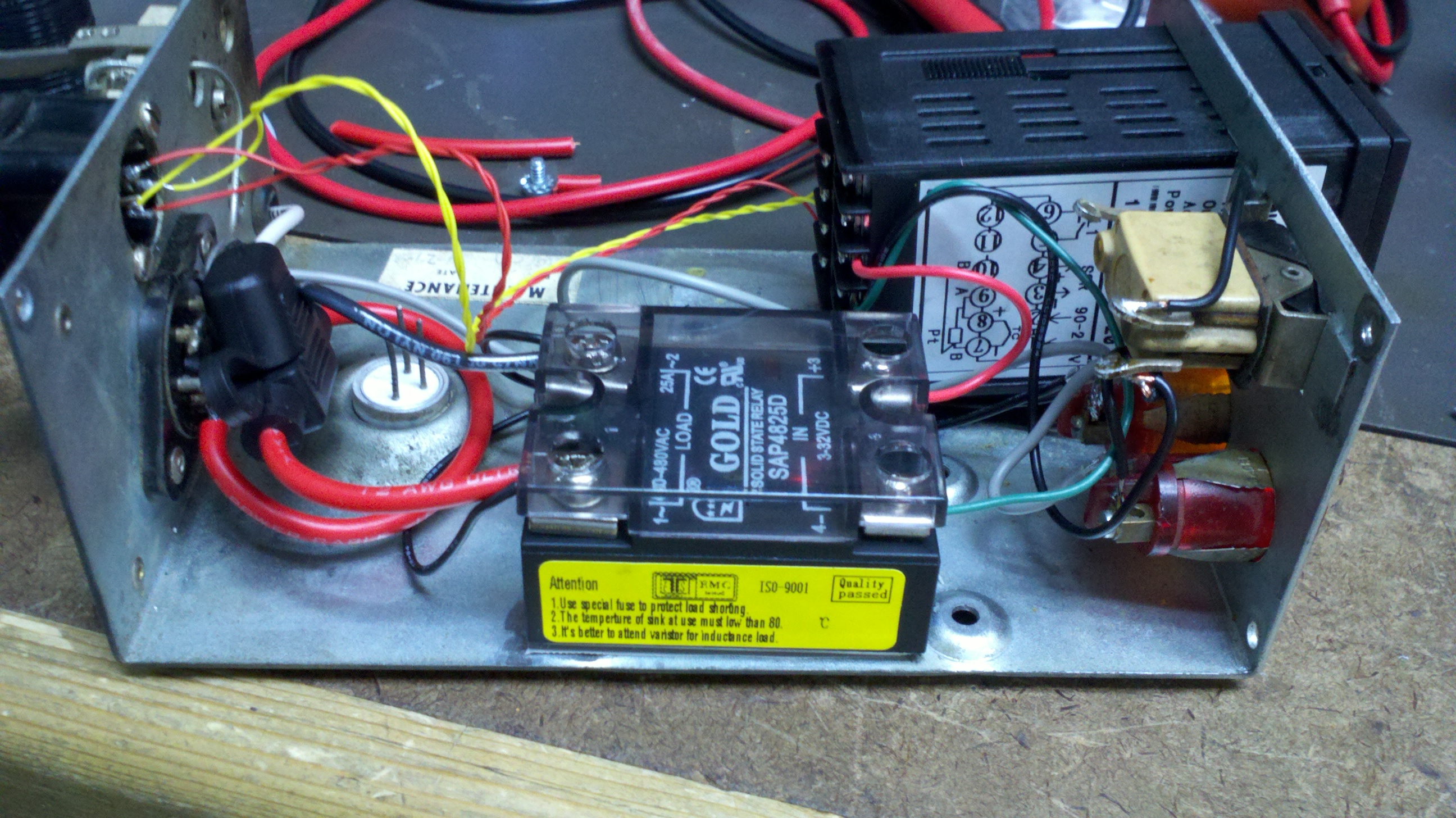

New SSR

New SSR

The new controller is super simple. It consists of an Off-the-Shelf PID controller from Amazon and a solid state relay from one of the bins in the i3Detroit e-lab.

Finished Install

Finished Install

When I was wiring up the new controller I made sure to use the old connectors for ease of use with the existing thermocouple in the machine.

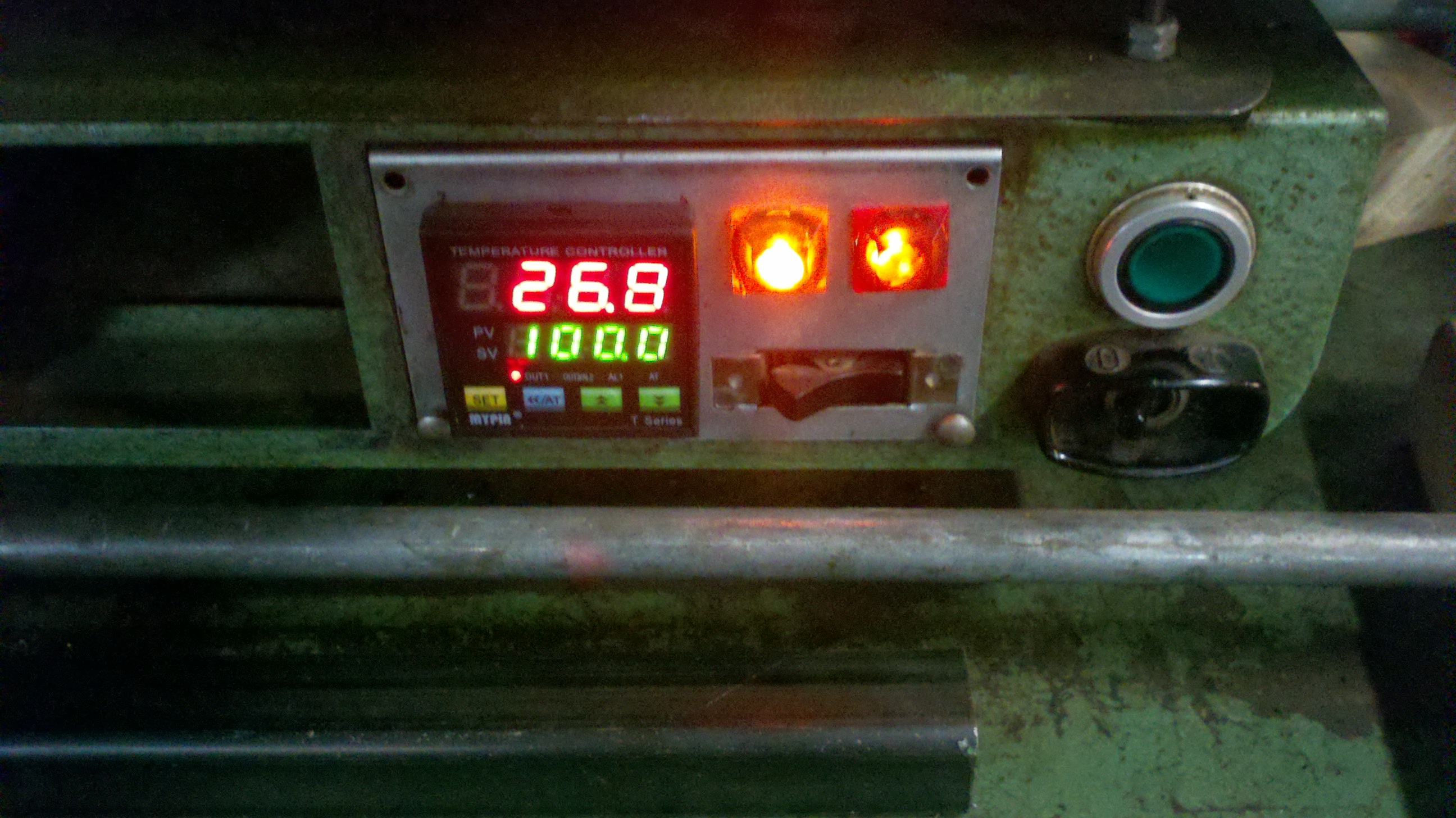

Working Controller

Working Controller

And it lives! All of this was repeated for the second controller.

tags: